-

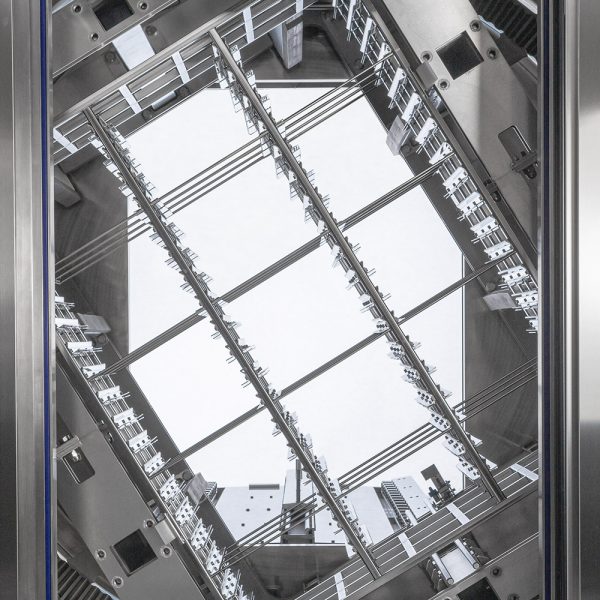

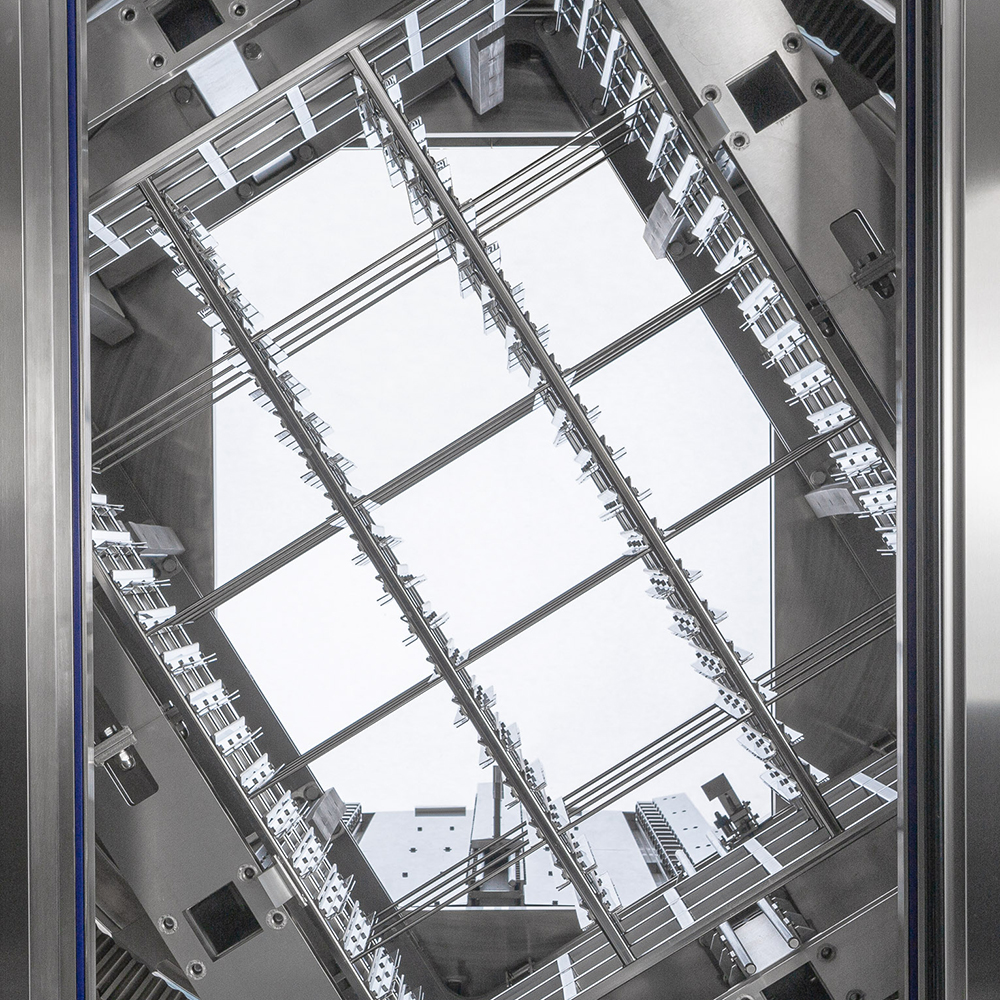

- Predefined and custom programmes for all needs. The machine process is developed by our Automation department in compliance with current regulations/standards and the type of product being sterilized.

- Terminal sterilization using a mixture of Air + Steam.

- A built-in ventilation system that mixes the clean steam and air together, thus creating the sterilization medium.

This processing method is recommended for complex plastic or glass containers, such as pre-filled syringes or vials in which condensate may form and become problematic for the finished product. The system ensures optimum heat distribution throughout the entire sterilization phase (temperature deviation less than ± 1°C). These autoclaves also feature an improved drying process, thanks to the ventilation system that prepares the unloaded product for labelling and packaging.

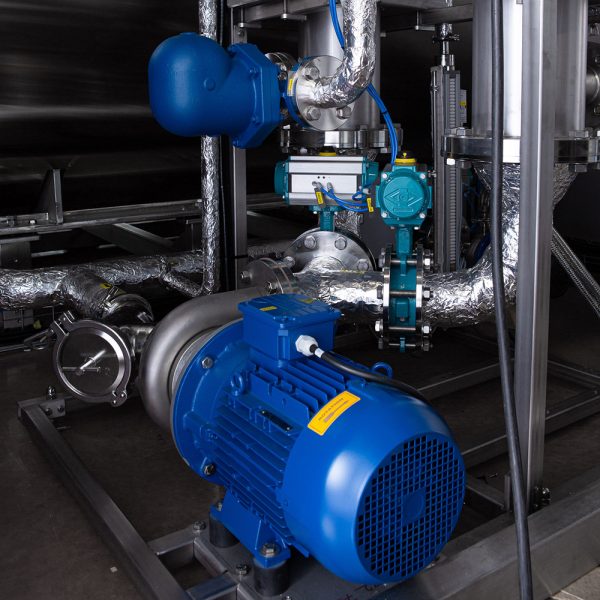

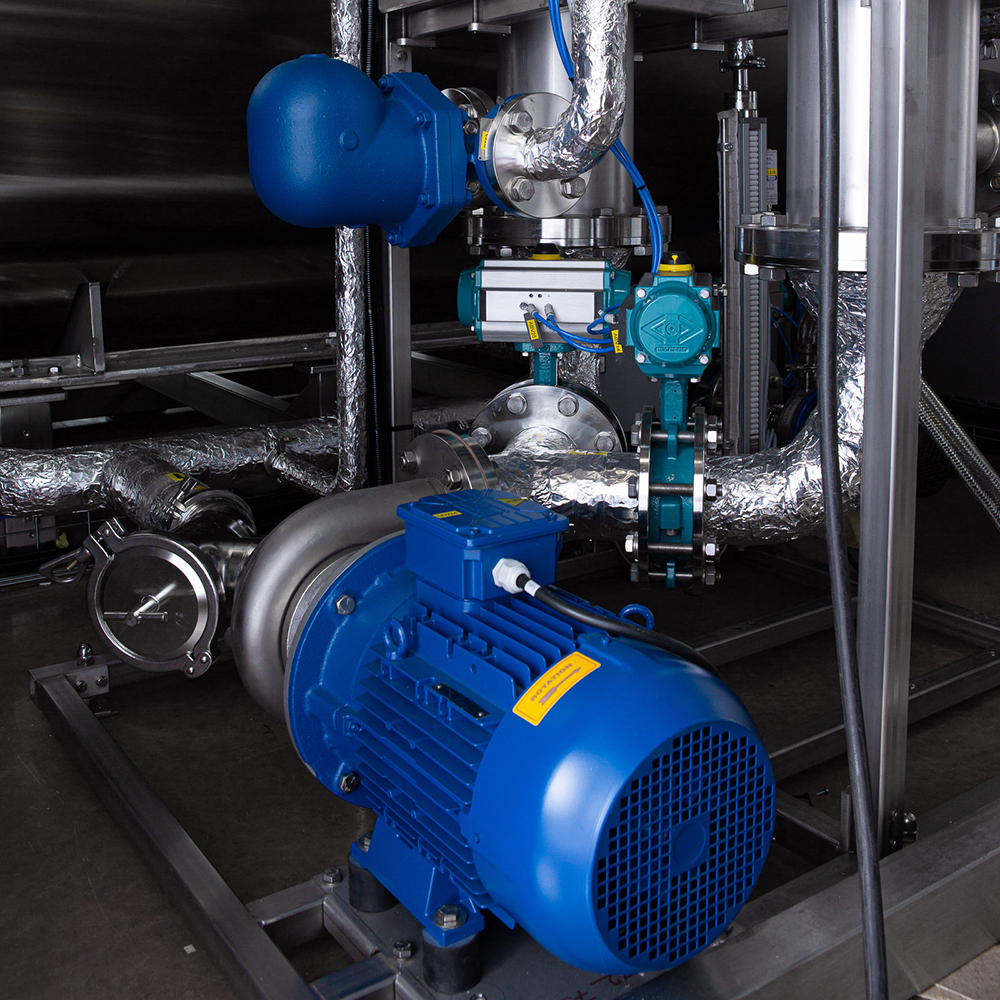

- Terminal sterilization using overheated Water.

A high-flow water recirculation system, thanks to the centrifugal pumps and “double-head multitube” heat exchangers which allow a “water” medium (WFI or PW) to be used as a means of transferring heat to warm up, sterilize and cool down the load. The system ensures optimum heat distribution throughout the entire sterilization phase (temperature deviation less than ± 1°C). This process method includes faster cycles but the treated product comes out still damp. Nevertheless, it is still the preferred method in most cases, due to its simplicity, cost-effectiveness and ease of validation.