These sterilizers feature a high-flow water recirculation system, thanks to the centrifugal pumps and “double-head multitube” heat exchangers which allow a “water” medium (WFI or PW) to be used as a means of transferring heat to warm up, sterilize and cool down the load. The system ensures optimum heat distribution throughout the entire sterilization phase (temperature deviation less than ± 1°C). This process method includes faster cycles but the treated product comes out still damp. It is, however, still the preferred method in most case due to its simplicity, cost-effectiveness and ease of validation.

TS-OW TYPE

cGMP TERMINAL STERILIZERS

TS-OW TYPE

cGMP TERMINAL STERILIZERS

These sterilizers are fitted with a high-flow water recirculation system, consisting of centrifugal pumps and “double-head multitube” heat exchangers. This system uses water (WFI or PW) as a means of transferring heat to warm up, sterilize and cool down the load. It guarantees an optimal heat distribution throughout the entire sterilization phase, with a temperature deviation of less than ±1°C. This method enables faster cycles, although the treated product remains damp. Nevertheless, it is often chosen for its simplicity, cost-effectiveness and ease of validation.

LIQUIDS

OVERHEATED WATER

105°C – 121°C

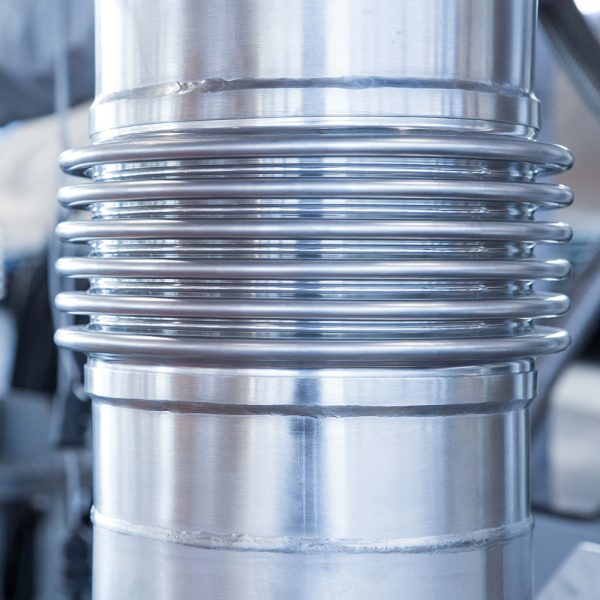

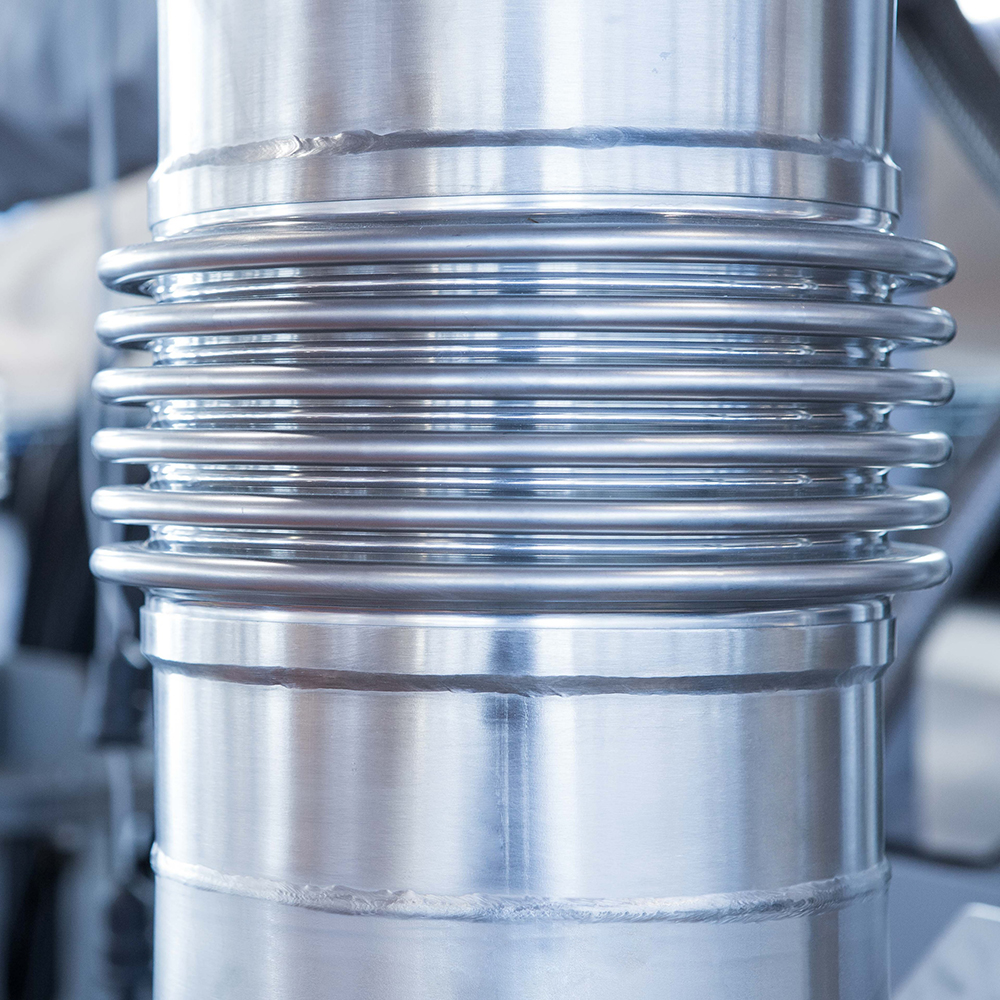

- Circular cross-section sterilization chamber with square or rectangular hatches (doors).

- The chamber of the TS OW model has a single wall (no jacket).

- Reinforcements are welded onto the outside of the chamber to ensure stable operating conditions.

- The chamber is placed on a base designed to evenly distribute the weight on the floor.

- The loading cart-insertion and removal guides are placed on the bottom of the chamber; they are also height-adjustable.

- The bottom of the chamber converges towards the drain sump to facilitate the condensation drain.

- Two 2” tri-clamp ferrules are welded to the chamber for validation purposes (temperature uniformity mapping and pressure tests).

- All of the chamber’s internal surfaces are mechanically polished and then undergo chemical degreasing, pickling and passivation treatments. Surface finish ≤ 0.35 micron.

- The chamber can be installed at floor level or in a pit (depending on the size).

mail

Subscribe to our newsletter

Stay up to date with the latest news from LAST Technology