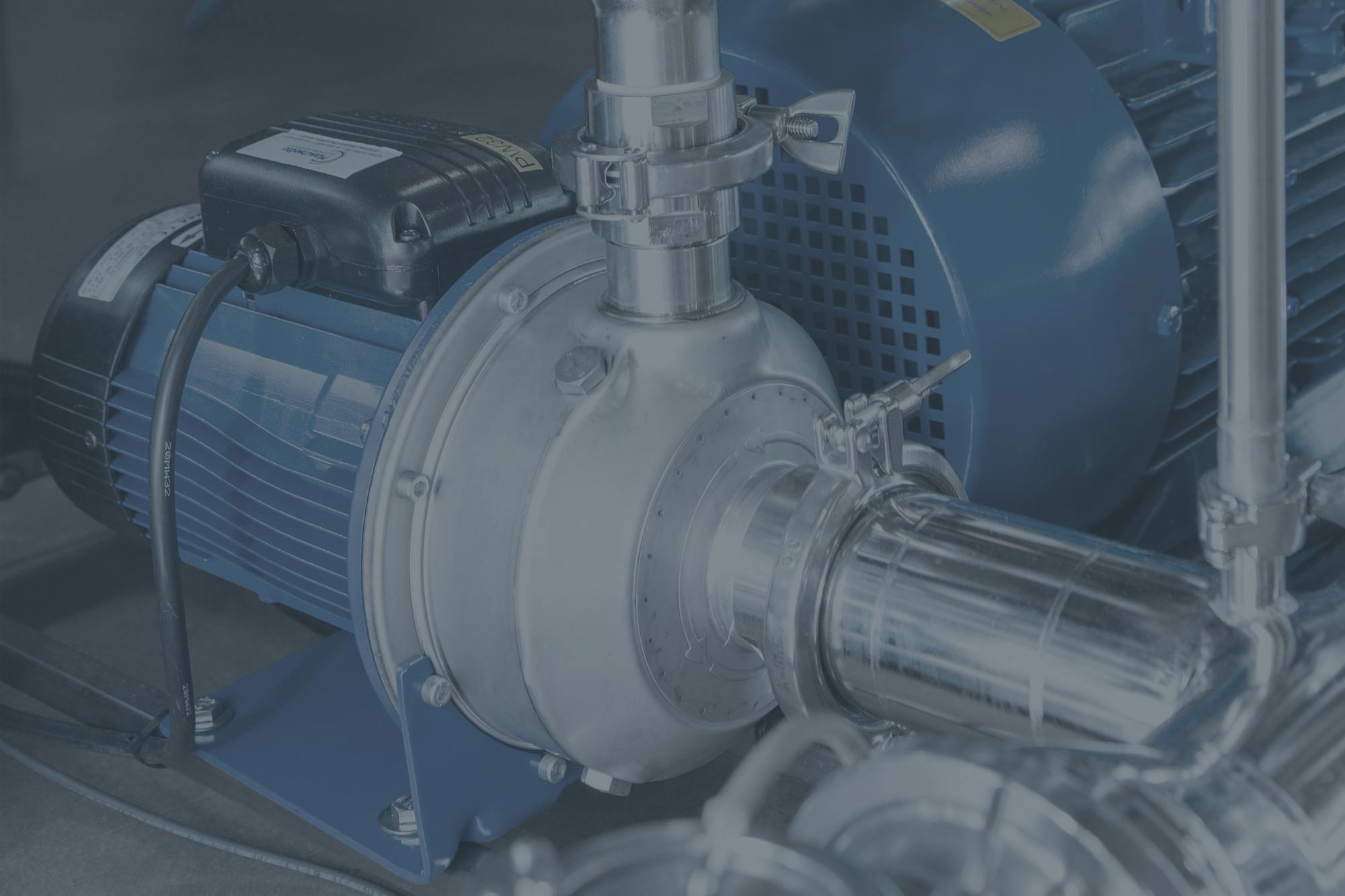

The steam generation process occurs through the heat exchange action between the water and heating element. Two types of heating systems are possible: electrical or indirect steam (industrial). f an electrical system is used, the heating units are directly immersed in the water (this system is also called “direct”). The indirect system, on the other hand, uses industrial steam which runs through a “coil” that is always immersed in water. Both systems can be equipped with a 0.2 µm cartridge filter and a water separation unit to ensure the cleanliness and saturation (condensation-free) of the generated clean steam.

- Circular container with a circular inspection flange (aka. “double-headed”).

- The heating elements (electric heating elements or “coil” tube bundle for indirect heating) are housed directly on the inspection flange.

- The container is positioned on a base that has been designed specifically to correctly distribute the equipment’s weight on the floor.

- The bottom of the container converges towards the main condensate drain.

- The container is equipped with1.5” tri-clamp ferrules for validation purposes.

- The internal surfaces, piping and all parts that come into contact with the product are mechanically polished. Ra finish: ≤ 0.35 micron.

- 0.2 µm cartridge filter integrated on the clean steam line (optional).

- Water separation device installed on the clean steam inlet line to ensure that the generated steam is saturated (free from condensation) [optional].

- Floor-mounted generator.

cGMP clean steam generators

PHARMA DIVISION

PHARMA DIVISION

cGMP clean steam generator description

The CSG steam generators have been designed to produce clean steam for use in sterilisation equipment processes.

![]() CLEAN SATURATED STEAM

CLEAN SATURATED STEAM

![]() WATER + ELECTRICITY or INDUSTRIAL STEAM

WATER + ELECTRICITY or INDUSTRIAL STEAM

![]() 121°C – 134°C

121°C – 134°C

The steam generation process occurs through the heat exchange action between the water and heating element. Two types of heating systems are possible: electrical or indirect steam (industrial). f an electrical system is used, the heating units are directly immersed in the water (this system is also called “direct”). The indirect system, on the other hand, uses industrial steam which runs through a “coil” that is always immersed in water. Both systems can be equipped with a 0.2 µm cartridge filter and a water separation unit to ensure the cleanliness and saturation (condensation-free) of the generated clean steam.

- Circular container with a circular inspection flange (aka. “double-headed”).

- The heating elements (electric heating elements or “coil” tube bundle for indirect heating) are housed directly on the inspection flange.

- The container is positioned on a base that has been designed specifically to correctly distribute the equipment’s weight on the floor.

- The bottom of the container converges towards the main condensate drain.

- The container is equipped with1.5” tri-clamp ferrules for validation purposes.

- The internal surfaces, piping and all parts that come into contact with the product are mechanically polished. Ra finish: ≤ 0.35 micron.

- 0.2 µm cartridge filter integrated on the clean steam line (optional).

- Water separation device installed on the clean steam inlet line to ensure that the generated steam is saturated (free from condensation) [optional].

- Floor-mounted generator.

cGMP clean steam generators

PHARMA DIVISION

PHARMA DIVISION

cGMP clean steam generator description

The CSG steam generators have been designed to produce clean steam for use in sterilisation equipment processes.

![]() CLEAN SATURATED STEAM

CLEAN SATURATED STEAM

![]() WATER + ELECTRICITY or INDUSTRIAL STEAM

WATER + ELECTRICITY or INDUSTRIAL STEAM

![]() 121°C – 134°C

121°C – 134°C

cGMP clean steam generators

PHARMA DIVISION

PHARMA DIVISION

cGMP clean steam generator description

The CSG steam generators have been designed to produce clean steam for use in sterilisation equipment processes.

![]() CLEAN SATURATED STEAM

CLEAN SATURATED STEAM

![]() WATER + ELECTRICITY or INDUSTRIAL STEAM

WATER + ELECTRICITY or INDUSTRIAL STEAM

![]() 121°C – 134°C

121°C – 134°C

The steam generation process occurs through the heat exchange action between the water and heating element. Two types of heating systems are possible: electrical or indirect steam (industrial). f an electrical system is used, the heating units are directly immersed in the water (this system is also called “direct”). The indirect system, on the other hand, uses industrial steam which runs through a “coil” that is always immersed in water. Both systems can be equipped with a 0.2 µm cartridge filter and a water separation unit to ensure the cleanliness and saturation (condensation-free) of the generated clean steam.

- Circular container with a circular inspection flange (aka. “double-headed”).

- The heating elements (electric heating elements or “coil” tube bundle for indirect heating) are housed directly on the inspection flange.

- The container is positioned on a base that has been designed specifically to correctly distribute the equipment’s weight on the floor.

- The bottom of the container converges towards the main condensate drain.

- The container is equipped with1.5” tri-clamp ferrules for validation purposes.

- The internal surfaces, piping and all parts that come into contact with the product are mechanically polished. Ra finish: ≤ 0.35 micron.

- 0.2 µm cartridge filter integrated on the clean steam line (optional).

- Water separation device installed on the clean steam inlet line to ensure that the generated steam is saturated (free from condensation) [optional].

- Floor-mounted generator.

We may be small, but we can achieve great things.

Thanks to our customisable after-sales service packages, we offer solutions to suit every need. Choose the one that suits you best!

Customisation is quick and easy

Keep up to date with the latest news from the Last Technology worldand let us steer you towards the most suitable service for you!