Pre-selected and custom programmes for all needs. The machine process is developed by our Automation Department in compliance with current codes/standards and the type of product being processed. Products go from dirty to being ready to be sterilised, through a pre-wash, chemical wash, rinse and final hot air drying phase (HEPA 13-filtered) whilst also keeping the water TOC level, conductivity and pH level under control. During the product wash phase, chemicals can be injected by means of a precise and reliable system, in order to improve the machine’s cleaning efficiency.

AQUA TYPE – GLASSWARE WASHERS

cGLP GLASSWARE WASHERS

AQUA TYPE – GLASSWARE WASHERS

cGLP GLASSWARE WASHERS

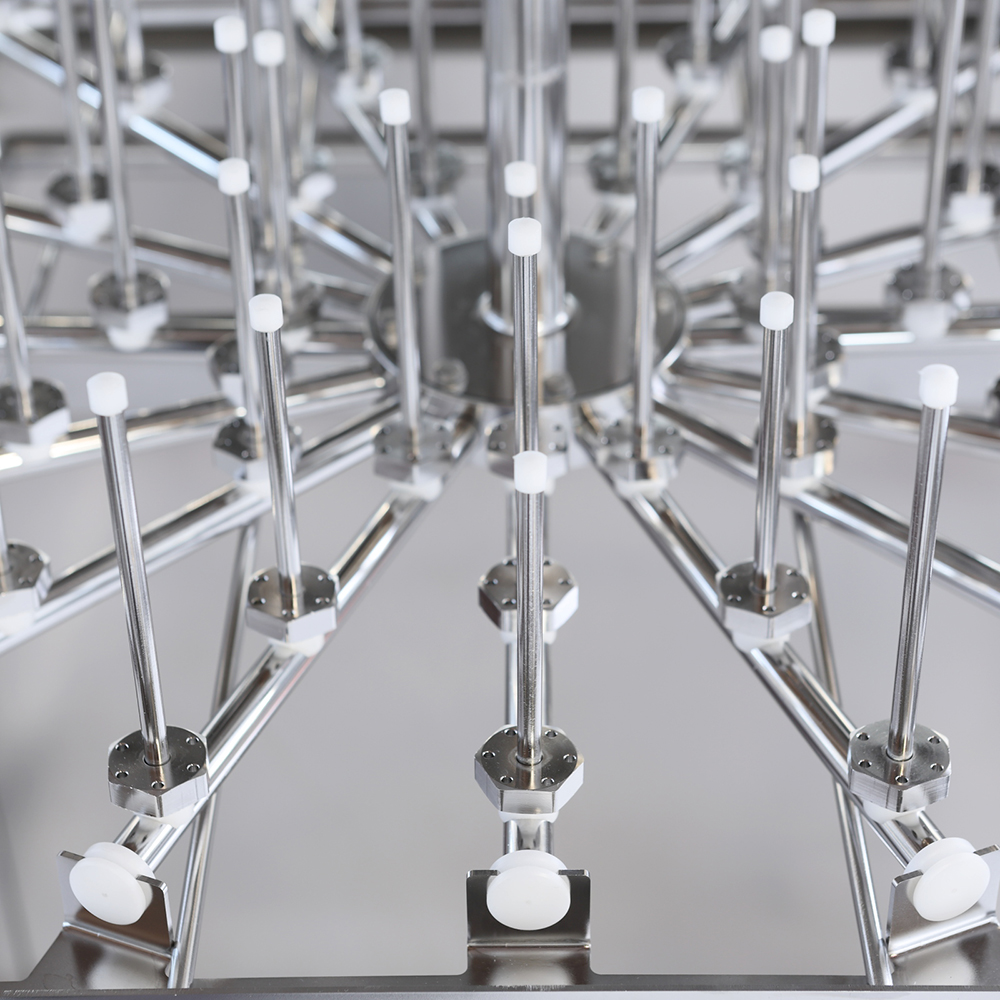

The AQUA washing equipment is specifically designed for washing, chemical and/or thermal disinfecting, decontaminating and drying of materials used in research laboratories, such as: glassware, metal parts, and plastic and rubber components, etc.

SOLIDS AND SEMI-SOLIDS

WATER + DETERGENTS OR SOLVENTS + AIR

20°C – 120°C

- Double-wall square or rectangular cross-section chamber, made entirely of 316L or 316Ti stainless steel.

- Innovative central water collection tank made of 316L or 316Ti stainless steel.

- Rigid pipes and air ducts made entirely of 316L stainless steel with flanged connections.

- 3-degree incline of the pipes towards the floor drain.

- Any surfaces in contact with the product are mechanically satin-finished to a roughness level lower than 1 micron.

- Rounded internal chamber corners to ensure perfect hygiene.

- Manual folding chamber doors or vertical/horizontal automatic sliding doors (door structure made of 316L or 316Ti stainless steel with a HST tempered glass inspection window).

- Silicone chamber door sealing gasket with an innovative design.

- Components and tools made of 316L/316Ti stainless steel and elastomers in compliance with FDA 21 CFR, Part 177.

- The chamber pipes, components and instruments are suitably insulated with high-tech material.

- Area separation by means of a 304 or 316L/316Ti stainless steel “bio-seal” frame.

- Brand-new design that connects the utilities to the internal cart, complete with an automatic locking and release system (100% seal guaranteed).

- Manual or fully automated ergonomic product loading and unloading solutions.

- Floor-level or elevated loading solutions.

mail

Subscribe to our newsletter

Stay up to date with the latest news from LAST Technology