Pre-selected and custom programmes for every need. The equipment process is developed by our Automation Department, according to the current codes/standards and the type of product to be processed. Products go from dirty to ready to be sterilised, by means of a pre-wash, chemical-added wash, rinse and final hot air drying phase (HEPA 13 filtered). Whilst also keeping the water TOC level, conductivity and pH level under control. During the product wash phase, chemicals can be injected by means of a precise and reliable system, in order to improve the equipment’s cleaning action.

- Single-walled square or rectangular chamber, made entirely from 316L or 316Ti stainless steel.

- The innovative central water collection tank is also made of 316L or 316Ti stainless steel.

- The rigid piping and air ducts are made entirely from 316L stainless steel with flanged connections.

- The pipes incline 3° towards the floor drain.

- Any surfaces that come into contact with the product are mechanically satin-finished to a roughness level of less than 1 micron.

- Rounded internal chamber corners to ensure perfect hygiene.

- Manual folding chamber doors or vertical/horizontal automatic sliding doors (316L or 316Ti stainless steel door with a HST tempered glass

- Silicone chamber door sealing gasket with an innovative design.

- 316L/316Ti stainless steel components and tools, in addition to elastomers manufactured in compliance with FDA 21 CFR, Part 177.

- The chamber, heads, pipes, components and instruments are properly insulated by a cutting-edge material.

- Zone separation by means of a 304 or 316L/316Ti stainless steel “bio-seal” septum.

- A brand-new design that connects the utilities to the internal trolley, complete with an automatic locking and unlocking system (100% seal guaranteed)

- Manual or fully automated ergonomic product loading and unloading solutions.

- Floor or elevated loading solutions.

cGLP washing equipment

LAB DIVISION

LAB DIVISION

Washing equipment description

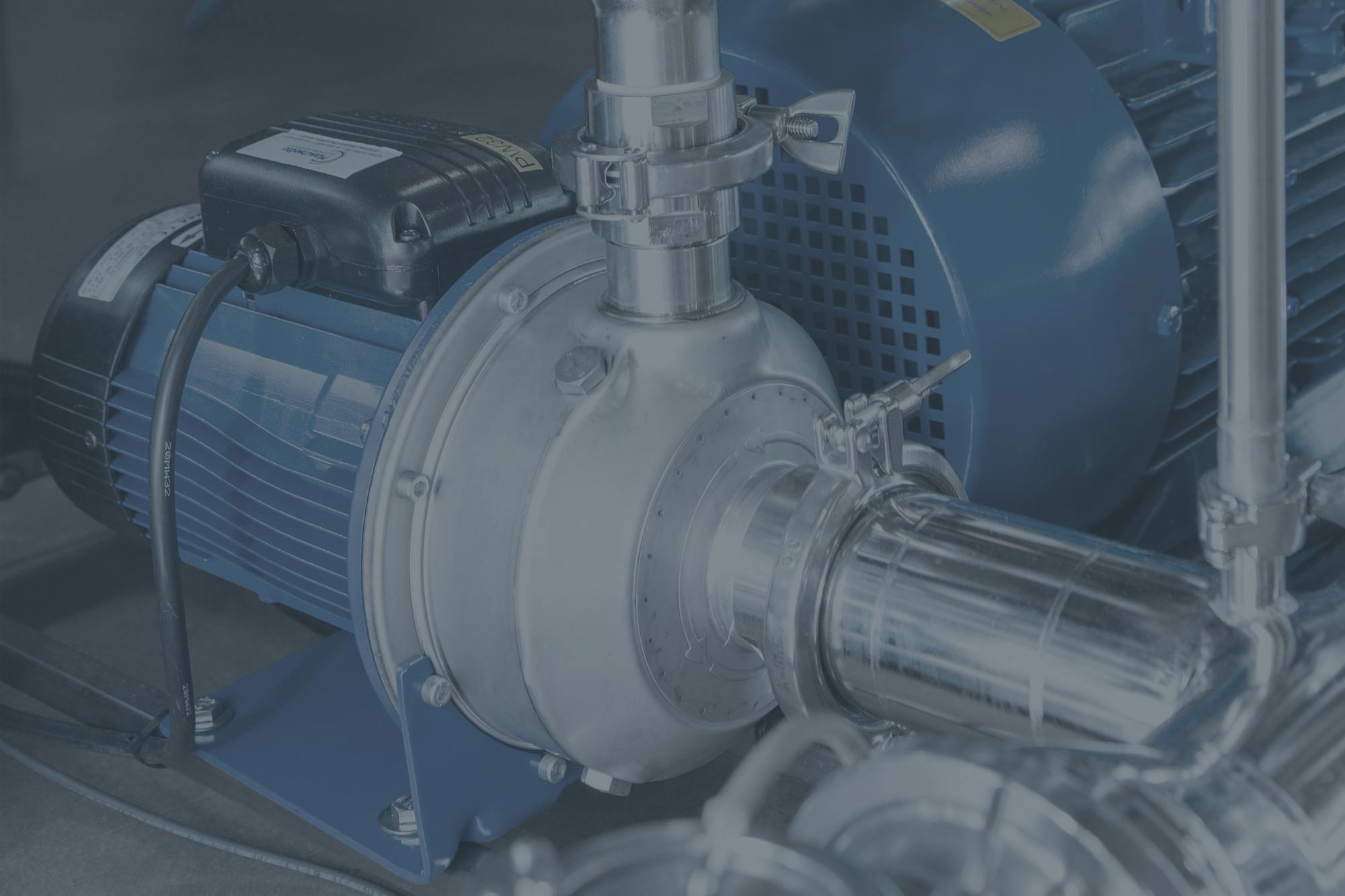

The AQUA washing equipment has been specifically designed to process wash, disinfect, decontaminate and dry materials used in research laboratories, such as: glassware, metal parts, and plastic and rubber components, etc.

![]() SOLIDS AND SEMI-SOLIDS

SOLIDS AND SEMI-SOLIDS

![]() WATER + CLEANERS or SOLVENTS + AIR

WATER + CLEANERS or SOLVENTS + AIR

![]() 20°C – 120°C

20°C – 120°C

Pre-selected and custom programmes for every need. The equipment process is developed by our Automation Department, according to the current codes/standards and the type of product to be processed. Products go from dirty to ready to be sterilised, by means of a pre-wash, chemical-added wash, rinse and final hot air drying phase (HEPA 13 filtered). Whilst also keeping the water TOC level, conductivity and pH level under control. During the product wash phase, chemicals can be injected by means of a precise and reliable system, in order to improve the equipment’s cleaning action.

- Single-walled square or rectangular chamber, made entirely from 316L or 316Ti stainless steel.

- The innovative central water collection tank is also made of 316L or 316Ti stainless steel.

- The rigid piping and air ducts are made entirely from 316L stainless steel with flanged connections.

- The pipes incline 3° towards the floor drain.

- Any surfaces that come into contact with the product are mechanically satin-finished to a roughness level of less than 1 micron.

- Rounded internal chamber corners to ensure perfect hygiene.

- Manual folding chamber doors or vertical/horizontal automatic sliding doors (316L or 316Ti stainless steel door with a HST tempered glass

- Silicone chamber door sealing gasket with an innovative design.

- 316L/316Ti stainless steel components and tools, in addition to elastomers manufactured in compliance with FDA 21 CFR, Part 177.

- The chamber, heads, pipes, components and instruments are properly insulated by a cutting-edge material.

- Zone separation by means of a 304 or 316L/316Ti stainless steel “bio-seal” septum.

- A brand-new design that connects the utilities to the internal trolley, complete with an automatic locking and unlocking system (100% seal guaranteed)

- Manual or fully automated ergonomic product loading and unloading solutions.

- Floor or elevated loading solutions.

cGLP washing equipment

LAB DIVISION

LAB DIVISION

Washing equipment description

The AQUA washing equipment has been specifically designed to process wash, disinfect, decontaminate and dry materials used in research laboratories, such as: glassware, metal parts, and plastic and rubber components, etc.

![]() SOLIDS AND SEMI-SOLIDS

SOLIDS AND SEMI-SOLIDS

![]() WATER + CLEANERS or SOLVENTS + AIR

WATER + CLEANERS or SOLVENTS + AIR

![]() 20°C – 120°C

20°C – 120°C

cGLP washing equipment

LAB DIVISION

LAB DIVISION

Washing equipment description

The AQUA washing equipment has been specifically designed to process wash, disinfect, decontaminate and dry materials used in research laboratories, such as: glassware, metal parts, and plastic and rubber components, etc.

![]() SOLIDS AND SEMI-SOLIDS

SOLIDS AND SEMI-SOLIDS

![]() WATER + CLEANERS or SOLVENTS + AIR

WATER + CLEANERS or SOLVENTS + AIR

![]() 20°C – 120°C

20°C – 120°C

Pre-selected and custom programmes for every need. The equipment process is developed by our Automation Department, according to the current codes/standards and the type of product to be processed. Products go from dirty to ready to be sterilised, by means of a pre-wash, chemical-added wash, rinse and final hot air drying phase (HEPA 13 filtered). Whilst also keeping the water TOC level, conductivity and pH level under control. During the product wash phase, chemicals can be injected by means of a precise and reliable system, in order to improve the equipment’s cleaning action.

- Single-walled square or rectangular chamber, made entirely from 316L or 316Ti stainless steel.

- The innovative central water collection tank is also made of 316L or 316Ti stainless steel.

- The rigid piping and air ducts are made entirely from 316L stainless steel with flanged connections.

- The pipes incline 3° towards the floor drain.

- Any surfaces that come into contact with the product are mechanically satin-finished to a roughness level of less than 1 micron.

- Rounded internal chamber corners to ensure perfect hygiene.

- Manual folding chamber doors or vertical/horizontal automatic sliding doors (316L or 316Ti stainless steel door with a HST tempered glass

- Silicone chamber door sealing gasket with an innovative design.

- 316L/316Ti stainless steel components and tools, in addition to elastomers manufactured in compliance with FDA 21 CFR, Part 177.

- The chamber, heads, pipes, components and instruments are properly insulated by a cutting-edge material.

- Zone separation by means of a 304 or 316L/316Ti stainless steel “bio-seal” septum.

- A brand-new design that connects the utilities to the internal trolley, complete with an automatic locking and unlocking system (100% seal guaranteed)

- Manual or fully automated ergonomic product loading and unloading solutions.

- Floor or elevated loading solutions.

We may be small, but we can achieve great things.

Thanks to our customisable after-sales service packages, we offer solutions to suit every need. Choose the one that suits you best!

Customisation is quick and easy

Keep up to date with the latest news from the Last Technology world

and let us steer you towards the most suitable service for you!