Depyrogenation is an essential process in pharmaceutical manufacturing, as it allows the elimination of pyrogens-substances of bacterial origin, such as endotoxins, that can cause severe febrile reactions if introduced into the body. To ensure pharmaceutical safety and the quality of injectable products, each production step must be strictly controlled, and depyrogenation technologies represent one of the most advanced tools in this area.

In this article we review the methods currently used for depyrogenation, exploring the innovations that are helping to make the process safer, more efficient, and more compliant with international standards.

The main methods of depyrogenation

In pharmaceutical production, the removal of pyrogens can be done by different methods, depending on the type of material being processed and the characteristics of the finished product. The most common methods include:

- Thermal depyrogenation

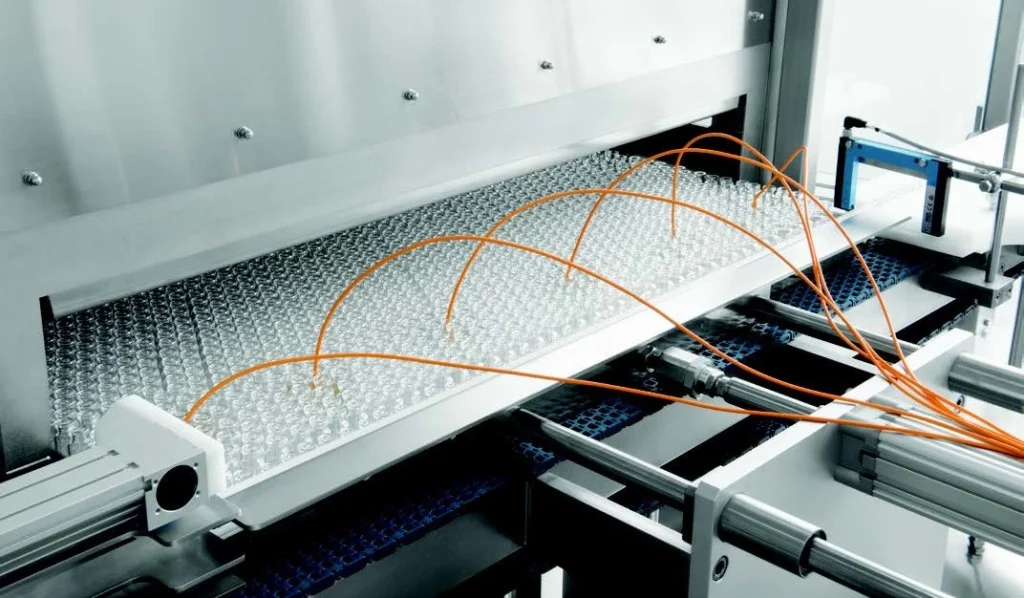

This is the most established method. It involves the use of high temperatures (up to 300°C) in tunnel or chamber ovens to destroy endotoxins present on glass, metals, or other heat-resistant materials. Due to its high level of effectiveness, it is considered a standard technique for sterilization and depyrogenation of containers such as vials and bottles before filling. - Membrane filtration

For heat-sensitive liquids, the safest approach is membrane filtration, which does not eliminate pyrogens but prevents their passage through pores smaller than 0.1 µm. It is particularly suitable for injectable solutions and biological products. In many cases, it is combined with monitoring technologies to verify the purity of the liquid output. - Innovative solutions

In recent years, alternative technologies, such as cold plasma processing, the use of UV-C radiation, and advanced oxidation methods that can break down pyrogens without compromising delicate materials, have been emerging. These innovations offer new possibilities especially in the processing of complex medical devices or heat-sensitive materials.

Depirogenation and pharmaceutical safety: an indispensable combination

Pharmaceutical safety depends largely on the ability to maintain sterile environments free of pyrogenic contaminants. Endotoxins are highly resistant and can be present even after standard sterilization, which is why depirogenation is a must in the production of injectable drugs, vaccines, and biologic therapies.

Modern depirogenation technologies offer greater control of critical parameters, such as temperature, exposure and airflow, ensuring easier validation and full traceability of cycles. Integration with digital systems and smart sensors also enables real-time process monitoring, reducing the risk of errors and improving production efficiency.

With evolving regulations and increasing focus on patient safety, depyrogenation continues to be one of the most critical steps in pharmaceutical manufacturing. By leveraging established methods such as high temperature, and adopting innovative solutions, companies in the industry can improve the efficiency of their processes and ensure maximum pharmaceutical safety. Investing in advanced depyrogenation technologies is not just about complying with standards-it is a strategic step toward more reliable, sustainable and future-oriented manufacturing.