These sterilisers are fitted with an integrated ventilation system that mixes the clean steam and air together, thus creating the sterilisation medium.

This process method is recommended for complex plastic or glass containers, such as pre-filled syringes or vials in which condensate may form and become problematic for the finished product. The system ensures optimum heat distribution throughout the entire sterilisation phase (temperature deviation below ± 1°C). These autoclaves also boast a better drying process, thanks to the ventilation system that prepares the unloaded product for labelling and packaging.

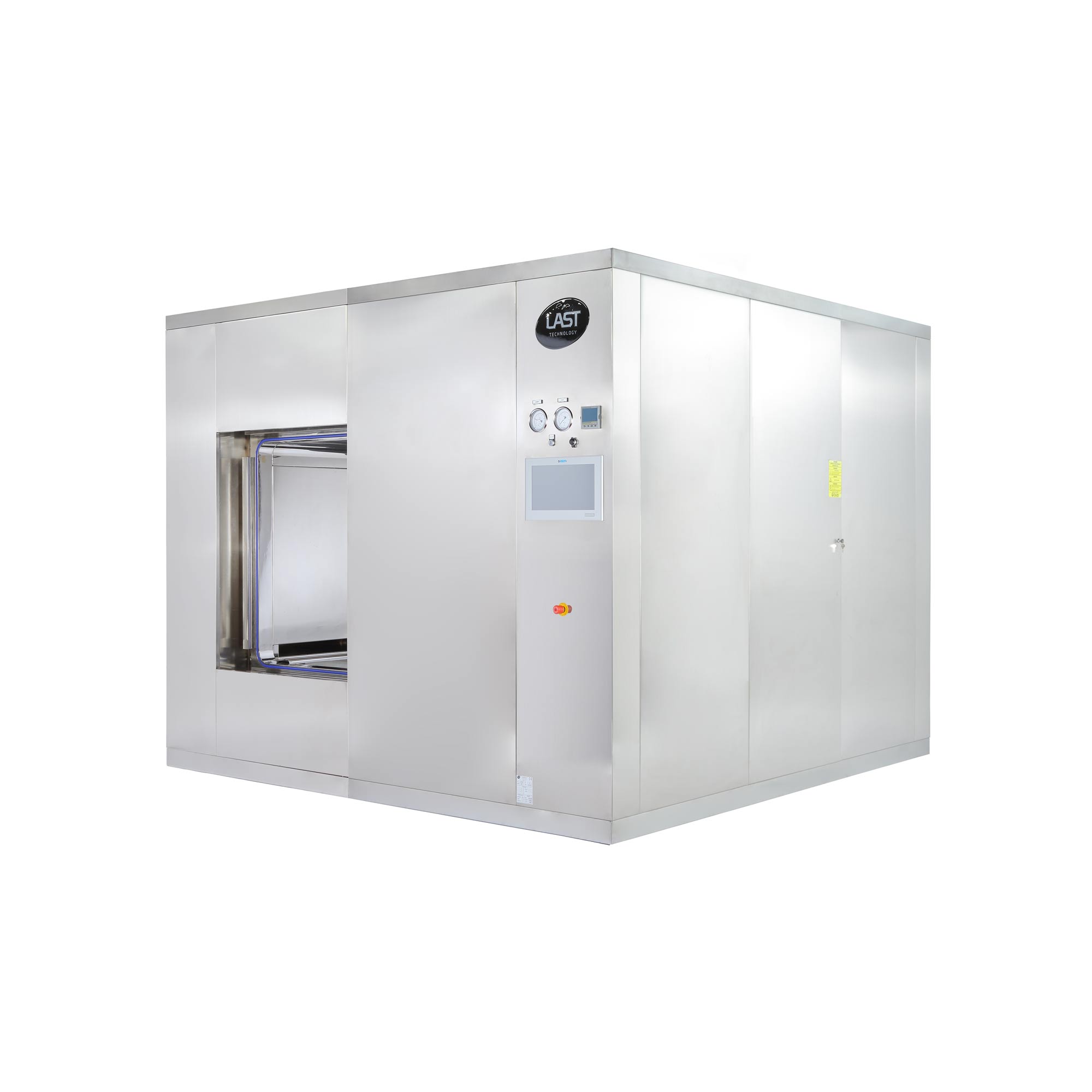

- Circular sterilisation chamber with square or rectangular hatches (doors).

- The TS-AS model boasts a flat/circular cavity that completely envelopes the chamber to quickly and uniformly heat/cool the loads.

- The TS-OW model is single-walled (no cavity).

- Some reinforcements are welded onto the outside of the chamber and/or cavity to ensure stability during operating conditions..

- The chamber is positioned on a base that has been designed specifically to evenly distribute the weight on the floor.

- The loading trolley-inserting and removing guides are positioned on the bottom of the chamber; they are also height-adjustable.

- The bottom of the chamber converges towards the drain sump in order to make disposing of the condensate easier.

- Two 2” tri-clamp ferrules are welded to the chamber for validation purposes (temperature uniformity mapping and pressure tests).

- All of the chambers internal surfaces are mechanically polished and then subjected to chemical degreasing, pickling and passivation treatments. Surface finish: ≤ 0.35 micron.

- Above-floor or recessed chamber installation possible (depending on the size).

cGMP terminal sterilisers

PHARMA DIVISION

PHARMA DIVISION

cGMP terminal steriliser description

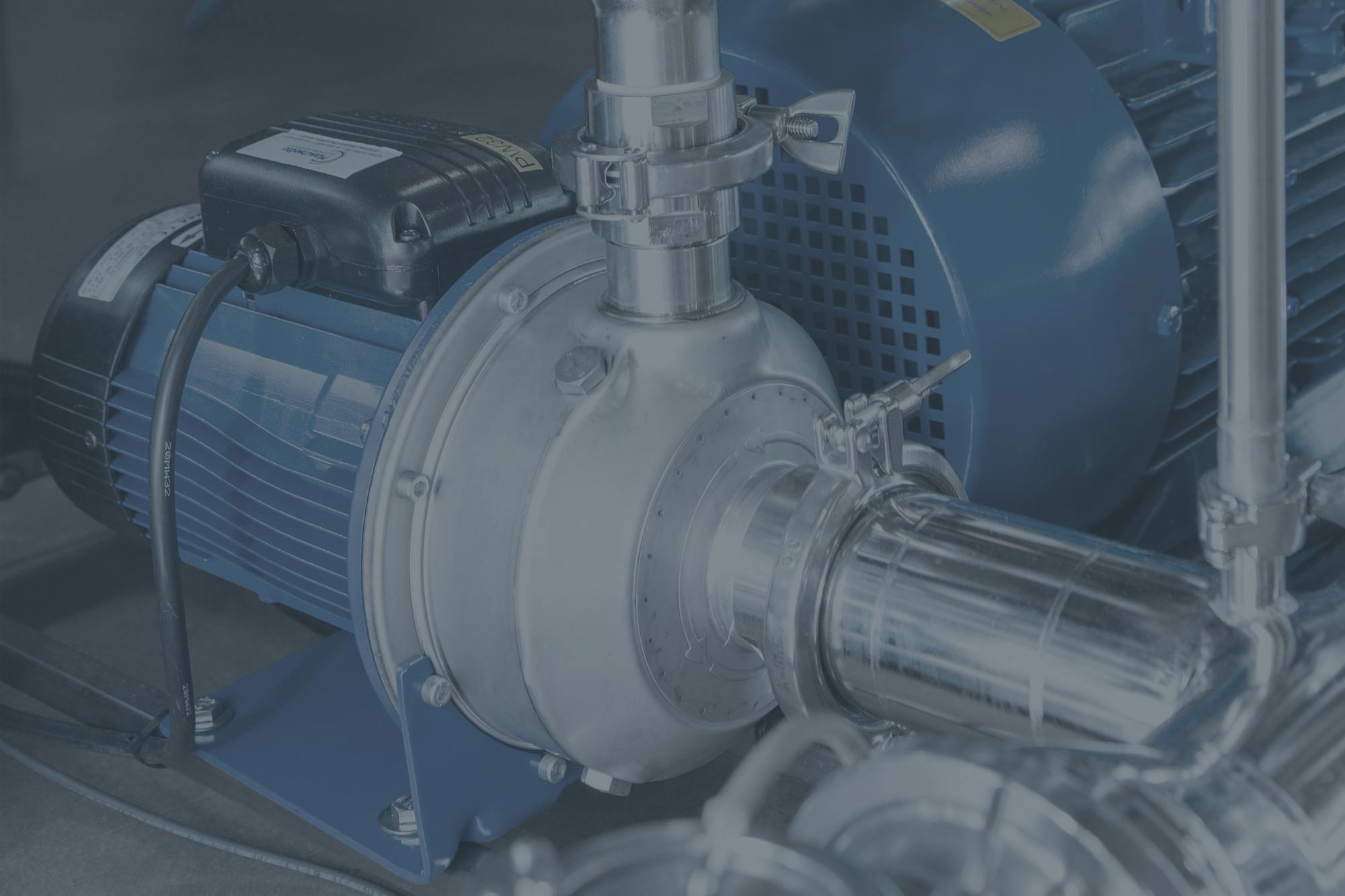

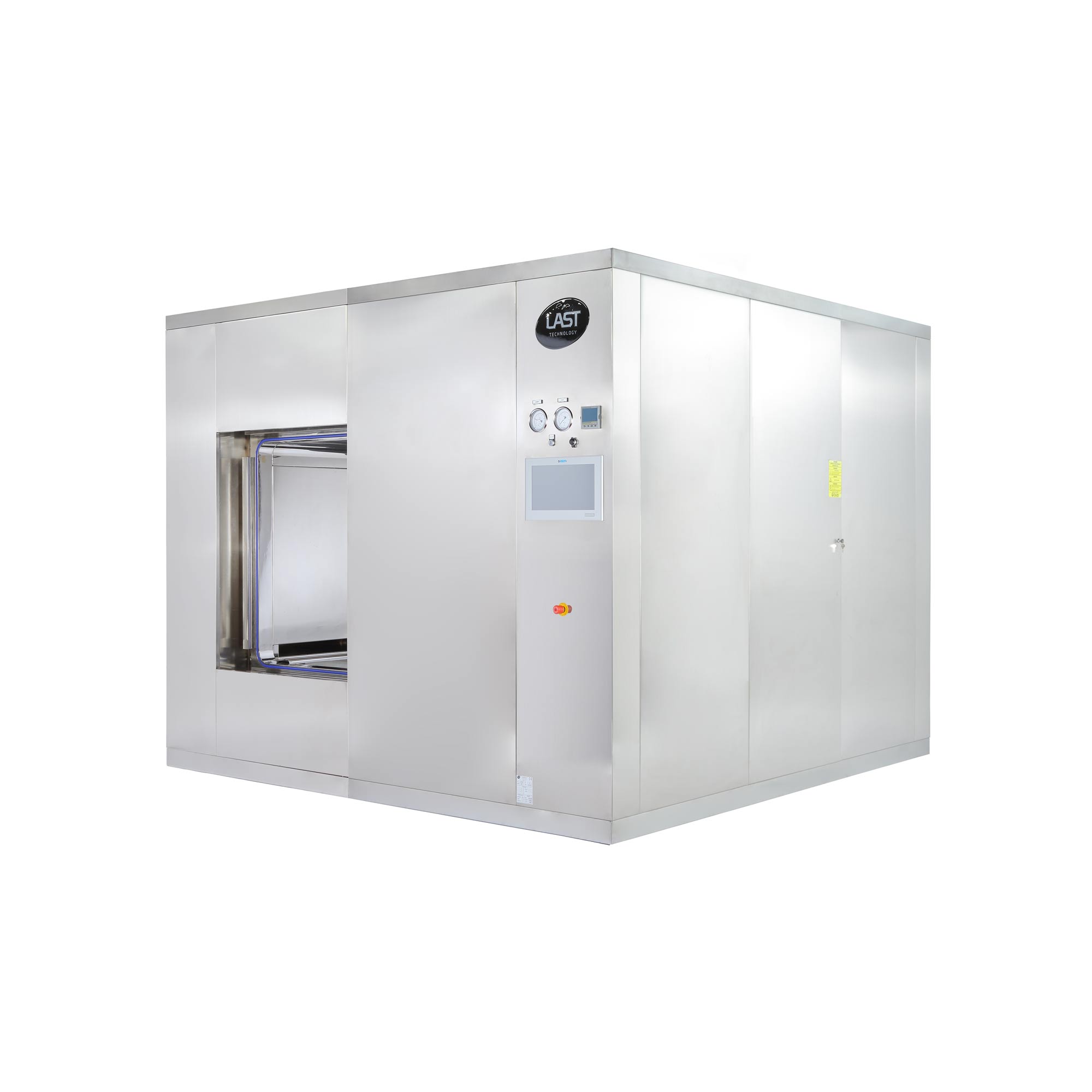

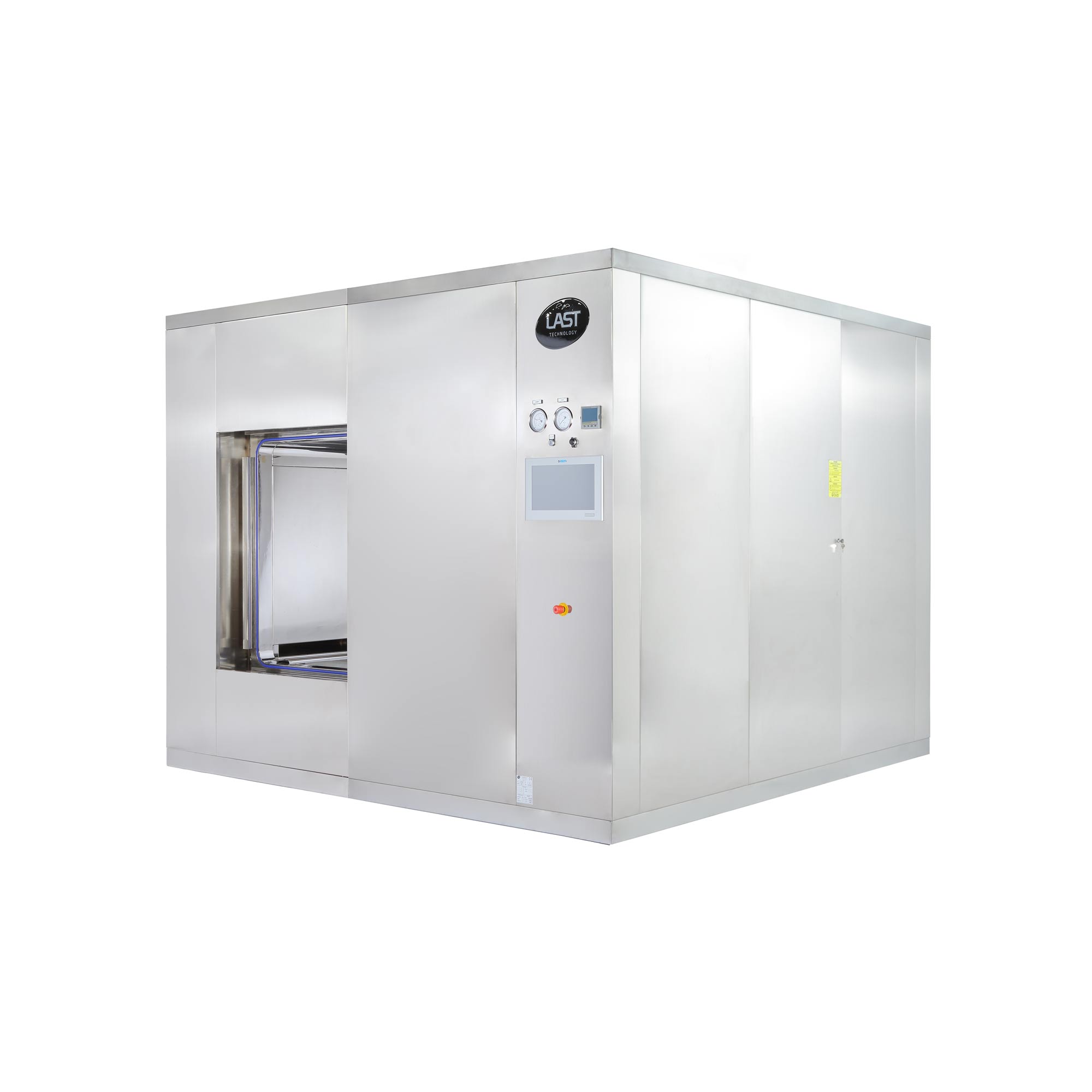

The TS-AS and TS-OW autoclaves have been specifically designed to terminally sterilise liquids in sealed containers, such as plastic bags, glass bottles, BFS bottles, syringes, vials, etc. In fact, their design allows for automatic variable pressure compensation based on the temperature difference (ΔT) of the product probes (RTD) inserted on a “sample” container. This type of check prevents the plastic containers from deforming, becoming damaged and changing colour.

![]() LIQUIDS

LIQUIDS

![]() MIXED AIR + STEAM

MIXED AIR + STEAM

![]() 105°C – 121°C

105°C – 121°C

These sterilisers are fitted with an integrated ventilation system that mixes the clean steam and air together, thus creating the sterilisation medium.

This process method is recommended for complex plastic or glass containers, such as pre-filled syringes or vials in which condensate may form and become problematic for the finished product. The system ensures optimum heat distribution throughout the entire sterilisation phase (temperature deviation below ± 1°C). These autoclaves also boast a better drying process, thanks to the ventilation system that prepares the unloaded product for labelling and packaging.

- Circular sterilisation chamber with square or rectangular hatches (doors).

- The TS-AS model boasts a flat/circular cavity that completely envelopes the chamber to quickly and uniformly heat/cool the loads.

- The TS-OW model is single-walled (no cavity).

- Some reinforcements are welded onto the outside of the chamber and/or cavity to ensure stability during operating conditions..

- The chamber is positioned on a base that has been designed specifically to evenly distribute the weight on the floor.

- The loading trolley-inserting and removing guides are positioned on the bottom of the chamber; they are also height-adjustable.

- The bottom of the chamber converges towards the drain sump in order to make disposing of the condensate easier.

- Two 2” tri-clamp ferrules are welded to the chamber for validation purposes (temperature uniformity mapping and pressure tests).

- All of the chambers internal surfaces are mechanically polished and then subjected to chemical degreasing, pickling and passivation treatments. Surface finish: ≤ 0.35 micron.

- Above-floor or recessed chamber installation possible (depending on the size).

cGMP terminal sterilisers

PHARMA DIVISION

PHARMA DIVISION

cGMP terminal steriliser description

The TS-AS and TS-OW autoclaves have been specifically designed to terminally sterilise liquids in sealed containers, such as plastic bags, glass bottles, BFS bottles, syringes, vials, etc. In fact, their design allows for automatic variable pressure compensation based on the temperature difference (ΔT) of the product probes (RTD) inserted on a “sample” container. This type of check prevents the plastic containers from deforming, becoming damaged and changing colour.

![]() LIQUIDS

LIQUIDS

![]() MIXED AIR + STEAM or SUPERHEATED WATER

MIXED AIR + STEAM or SUPERHEATED WATER

![]() 105°C – 121°C

105°C – 121°C

cGMP terminal sterilisers

PHARMA DIVISION

PHARMA DIVISION

cGMP terminal steriliser description

The TS-AS and TS-OW autoclaves have been specifically designed to terminally sterilise liquids in sealed containers, such as plastic bags, glass bottles, BFS bottles, syringes, vials, etc. In fact, their design allows for automatic variable pressure compensation based on the temperature difference (ΔT) of the product probes (RTD) inserted on a “sample” container. This type of check prevents the plastic containers from deforming, becoming damaged and changing colour.

![]() LIQUIDS

LIQUIDS

![]() MIXED AIR + STEAM or SUPERHEATED WATER

MIXED AIR + STEAM or SUPERHEATED WATER

![]() 105°C – 121°C

105°C – 121°C

These sterilisers are fitted with an integrated ventilation system that mixes the clean steam and air together, thus creating the sterilisation medium.

This process method is recommended for complex plastic or glass containers, such as pre-filled syringes or vials in which condensate may form and become problematic for the finished product. The system ensures optimum heat distribution throughout the entire sterilisation phase (temperature deviation below ± 1°C). These autoclaves also boast a better drying process, thanks to the ventilation system that prepares the unloaded product for labelling and packaging.

- Circular sterilisation chamber with square or rectangular hatches (doors).

- The TS-AS model boasts a flat/circular cavity that completely envelopes the chamber to quickly and uniformly heat/cool the loads.

- The TS-OW model is single-walled (no cavity).

- Some reinforcements are welded onto the outside of the chamber and/or cavity to ensure stability during operating conditions..

- The chamber is positioned on a base that has been designed specifically to evenly distribute the weight on the floor.

- The loading trolley-inserting and removing guides are positioned on the bottom of the chamber; they are also height-adjustable.

- The bottom of the chamber converges towards the drain sump in order to make disposing of the condensate easier.

- Two 2” tri-clamp ferrules are welded to the chamber for validation purposes (temperature uniformity mapping and pressure tests).

- All of the chambers internal surfaces are mechanically polished and then subjected to chemical degreasing, pickling and passivation treatments. Surface finish: ≤ 0.35 micron.

- Above-floor or recessed chamber installation possible (depending on the size).

We may be small, but we can achieve great things.

Thanks to our customisable after-sales service packages, we offer solutions to suit every need. Choose the one that suits you best!

Customisation is quick and easy

Keep up to date with the latest news from the Last Technology world<br>and let us steer you towards the most suitable service for you!